Information

Welcome To Hsinchu Refuse Resource Recovery Plant

Basic data of the incineration plant

- Site address: No. 240, Haibing Rd., Hsinchu City

- Designed treatment volume: 900 tones/day (2 incinerators) (designed heating value 2300 calories/kg)

- Construction period: Outsourced on March 31, 1994, completed in August 2000

- Area: 5.5 hectares

- Appearance: Pei Cobb Freed & Partners

- Stack: RC shell, 67 m high with two steel stacks

Main equipment

| Device name | Device Description |

|---|---|

| Garbage dumping door | 9 sets |

| Huge garbage dumping door | 3 sets |

| Garbage/ash truck platform scale (50 tones X2) | 1 set |

| Huge garbage cutting machine (hydraulic cutter) | 1 set |

| Garbage crane (overhead) | 2 units |

| Effective capacity of refuse bunker: | 10,800 m3 |

| Device name | Device Description |

|---|---|

| Capacity: | 450 tons/24 hrs./per incinerator |

| Temperature: | 850-1050 °C |

| Waste gas residence time: | More than 2 seconds |

| Device name | Device Description |

|---|---|

| Fly ash transport equipment | 2 sets |

| Fly ash storage capacity: | Total volume of 10-day operation (1,500 m3) |

| Bottom ash crane (overhead) | 2 units (1 standby) |

| Bottom ash bunker capacity: | Total volume of 5-day operation (250 m3) |

| Device name |

|---|

| Distributed control system (DCS), Chinese language display |

| Device name | Device Description |

|---|---|

| Cyclonic dust collector + semi-dry scrubber + bag filter dust collector | 2 sets |

| Device name | Device Description |

|---|---|

| Waste heat boiler (natural circulation) | 2 sets |

| Steam turbine generator (capacity 23,725 MW) | 1 set |

| Device name | Device Description |

|---|---|

| Physical and chemical treatment + fixed bed method + tertiary treatment | 1 set |

| Device name | Device Description |

|---|---|

| Deodorizer spraying device | 1 set |

| Device name | Device Description |

|---|---|

| Emergency generator (800 KW output) | 1 set |

| Car wash equipment | 2 sets |

| Continuous waste gas monitoring system | 2 sets |

Status quo of garbage disposal

The garbage disposed by the Hsinchu incineration plant is the combustible garbage from Hsinchu City and other counties/cities. The non-combustible garbage is disposed directly at the landfill.

Bottom and fly ash (including the fly ash and reaction products) are produced during incineration of the garbage. The former can be recycled. However, the latter contains heavy metal and may pollute the soil and groundwater to bring about secondary environmental pollution if not treated appropriately before being buried at the landfill. The fly ash should not be buried at the landfill unless it is solidified, the tested items of the solidified material dissolution test (e.g. mercury, arsenic, cadmium, chromium, lead, selenium, dioxin) comply with the environmental protection standard and the strength is more than 10kg/cm2.

The landfill is the final disposal site for the bottom ash and solidified material. It is protected with two layers of waterproof cloth and a complete set of monitoring mechanism. The incinerated bottom ash and solidified fly ash are well disposed at the landfill. Incinerating garbage can achieve the goal of reduction, stabilization, sanitization and detoxication, prevent the second environmental pollution and facilitate the recycling of resources. It can also conserve the rare landfill space, prolong the service life of the landfill and solve the garbage disposal problem effectively.

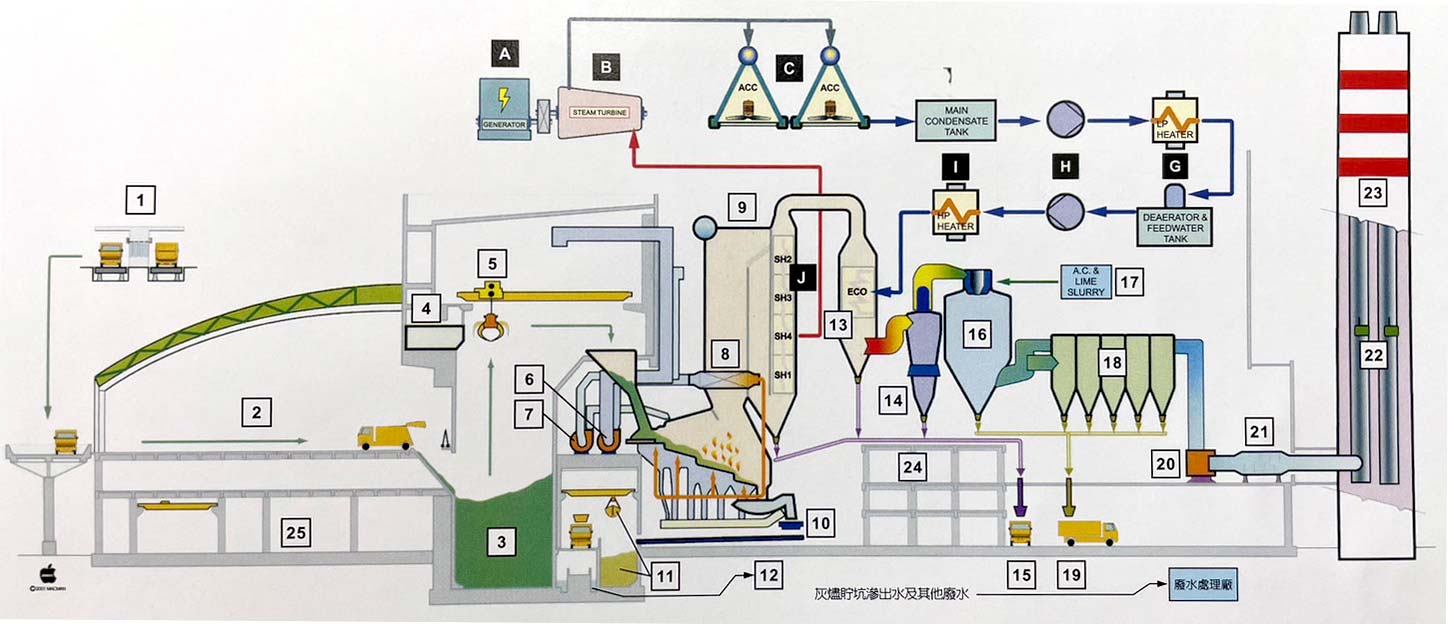

Refuse incineration process flow diagram

Explanation of refuse incineration process flow diagram

- AGenerator

- BSteam turbine

- CAir cooler condensate

- DCondensate water tank

- ECondensate water pump

- FLow pressure feedwater heater

- GDeaerator and feed water tank

- HBoiler feedwater pump

- IHigh pressure feedwater heater

- JSuperheater and superheated steam

- 1Weight bridge

- 2Refuse dumping area

- 3Refuse bunker

- 4Refuse crane control room

- 5Refuse crane

- 6Primary air fan

- 7Secondary air fan

- 8Primary air preheater

- 9Boiler

- 10Ash handling convey system

- 11Ash bunker and ash crane

- 12Refuse water leachate system

- 13Economizer

- 14Cyclone dust collector

- 15Fly ash convey system

- 16Semi-dry reactor

- 17Lime slurry inject system

- 18Bag filter dust collector

- 19Reaction product convey system

- 20Induced draft fan

- 21Reheating system

- 22Continuous emission monitoring system

- 23Stack

- 24Center control room

- 25Work station and storeroom

Pollution prevention equipment

Prevention of waste gas

An efficient high-performance waste gas treatment system is used to control the waste gas. The system comprises a combination of cyclone separator, semi-dry scrubber, active carbon and hydrated lime spraying equipment as well as bag filter duct collector to ensure that the emissions can meet the requirements of each environmental protection regulation.

Prevention of wastewater

The wastewater is fully recycled to achieve the goal of zero-discharge. The wastewater in the storage pit of high concentration garbage is directly sprayed in the incinerator, while the organic wastewater is recycled for operation of the plant after undergoing physical, chemical and biological treatment. As a result, there is nothing to be worried about regarding pollution of the environment.

Refuse treatment

The bottom ash produced during the incineration of the garbage is transported to the landfill by closed trucks. The fly ash and reaction product are transported to the fly ash solidification plant for treatment. They are then tested for conformity to the environmental protection standard and sent to the landfill.

Prevention of noise

The plant is a glass-curtain closed building that can block noise and vibration. Low-noise equipment is used for the plant to minimize the noise produced during the transportation. The plant conforms to the noise control standard both inside and outside of the area.

Prevention of effluvium

The garbage is transported by closed trucks to avoid leakage of effluvium. The air in the pit is drawn into the incinerator via an exhaust fan and used as the air for the incineration. The pressure of the pit is negative to avoid leakage of effluvium. The wastewater in the pit is directly sprayed into the incinerator and decomposed during the incineration. The effluvium adsorption equipment in the pit functions during the downtime of the incinerator to minimize the effluvium of the garbage.